Precision and Portability in Modern Laser Joining Techniques

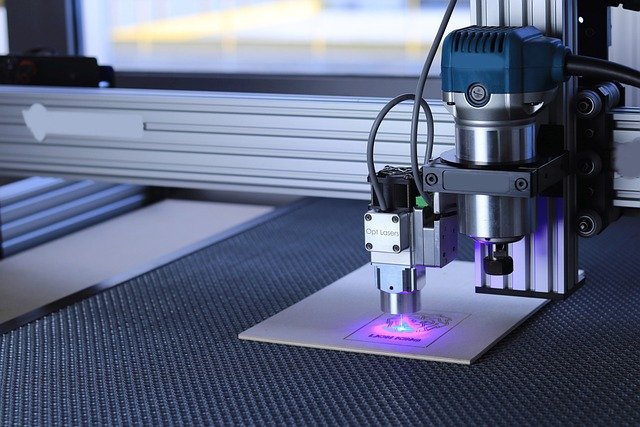

Laser welding has emerged as a transformative technology in various industries, offering a blend of precision and efficiency that traditional methods often cannot match. The evolution of this technology has led to the development of highly portable machines, making advanced joining techniques accessible for a wider range of applications. This shift empowers businesses and skilled professionals to perform intricate welding tasks with greater flexibility and accuracy, adapting to diverse operational environments.

Laser joining techniques represent a significant advancement in material processing, providing solutions for demanding applications across manufacturing, automotive, aerospace, and medical sectors. The ability of laser welding to create strong, clean welds with minimal heat input makes it a preferred choice for materials that are sensitive to thermal distortion or require high aesthetic quality. As technology continues to evolve, the accessibility and versatility of these systems are constantly improving, influencing how various industries approach fabrication and repair.

Understanding Portable Laser Welding Machines

Portable laser welding machines are compact, lightweight systems designed to bring the benefits of laser welding to various locations, from workshops to field operations. Unlike their larger industrial counterparts, these machines prioritize mobility without significantly compromising on performance. They typically integrate a laser source, optics, and a cooling system into a single, movable unit. This design allows for greater flexibility in manufacturing processes, on-site repairs, and prototyping, where moving the workpiece to a stationary welding station might be impractical or impossible. Advancements in fiber laser technology have been instrumental in making these units more robust, energy-efficient, and smaller, further enhancing their portability and ease of use.

Key Benefits and Applications of Laser Joining

Laser joining offers numerous advantages over conventional welding methods. One primary benefit is precision; the focused laser beam allows for very fine and accurate welds, crucial for intricate components and thin materials. This precision also translates to minimal heat-affected zones, reducing material distortion and the need for extensive post-welding finishing. The speed of laser welding can significantly boost productivity, as it often operates at higher travel speeds than traditional techniques. Furthermore, it can join a wide array of materials, including dissimilar metals, with high-quality results.

Applications for laser joining are diverse. In the automotive industry, it’s used for body-in-white assembly, battery welding, and intricate sensor components. Medical device manufacturing relies on laser welding for sterile, high-integrity joints in instruments and implants. Aerospace applications benefit from its ability to weld lightweight, high-strength alloys. Even in jewelry making and repair, portable laser welders offer unparalleled precision for delicate work.

Cost Considerations for Laser Welding Equipment

Investing in laser welding equipment involves several financial considerations. The initial purchase price of a portable laser welding machine can vary significantly based on laser power, features, brand reputation, and country of origin. Beyond the upfront cost, potential buyers should factor in operational expenses such as electricity consumption, consumables (e.g., shielding gas, protective optics), and maintenance. While laser welders generally have lower consumable costs compared to some traditional methods, specialized parts and technician services might be required for repairs. It is also important to consider training costs for operators, as laser welding requires specific skills and safety protocols.

| Product/Service | Provider | Cost Estimation (USD) |

|---|---|---|

| Handheld Fiber Laser Welder (1000W) | XYZ Laser Solutions | $15,000 - $25,000 |

| Compact Laser Welding System (500W) | ABC Welding Tech | $10,000 - $18,000 |

| Portable Pulsed Laser Welder (150J) | DEF Industrial | $20,000 - $35,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Enhancing Efficiency with Modern Laser Technology

Modern laser technology continues to push the boundaries of what is possible in material joining. Innovations in beam delivery systems, such as wobble welding and remote welding, allow for even greater flexibility and control, optimizing weld quality and speed. The integration of advanced sensors and software provides real-time monitoring and process control, further enhancing precision and repeatability. These technological advancements not only improve the quality of the weld but also contribute to a more efficient and safer working environment. As the technology becomes more refined and accessible, its adoption across various industries is expected to grow, facilitating the creation of more complex and durable products.

Safety Protocols and Operator Training

Operating laser welding machines requires strict adherence to safety protocols to prevent potential hazards. High-power lasers can cause severe eye damage and skin burns if proper precautions are not taken. Essential safety measures include the use of appropriate laser safety glasses, protective clothing, and ensuring the work area is properly enclosed or shielded. Furthermore, adequate ventilation is crucial to manage fumes and particulate matter generated during the welding process. Comprehensive operator training is indispensable, covering not only the technical aspects of machine operation but also a thorough understanding of all safety procedures and emergency protocols to ensure a safe working environment.

Modern laser joining techniques offer significant advantages in precision, speed, and versatility for various industrial applications. The development of portable laser welding machines has made this advanced technology more accessible, enabling efficient and high-quality fabrication and repair tasks in diverse settings. While initial investment and operational costs require careful consideration, the long-term benefits in terms of product quality, productivity, and material flexibility often outweigh these factors, making laser welding a valuable asset in contemporary manufacturing and repair processes.