Laser Welding Portability: Equipment Design and Function

Portable laser welding machines represent a significant advancement in industrial fabrication technology, combining precision welding capabilities with mobility features that enable on-site operations. These compact systems deliver focused laser beams to join materials with exceptional accuracy while maintaining the flexibility to work in various locations. Understanding their design principles, functional capabilities, and practical applications helps professionals make informed decisions about integrating portable laser welding solutions into their workflow.

Modern manufacturing demands increasingly flexible welding solutions that can adapt to diverse working environments. Portable laser welding machines address this need by incorporating advanced laser technology into compact, mobile platforms that maintain professional-grade performance standards.

Portable Laser Welding Machines Technology Overview

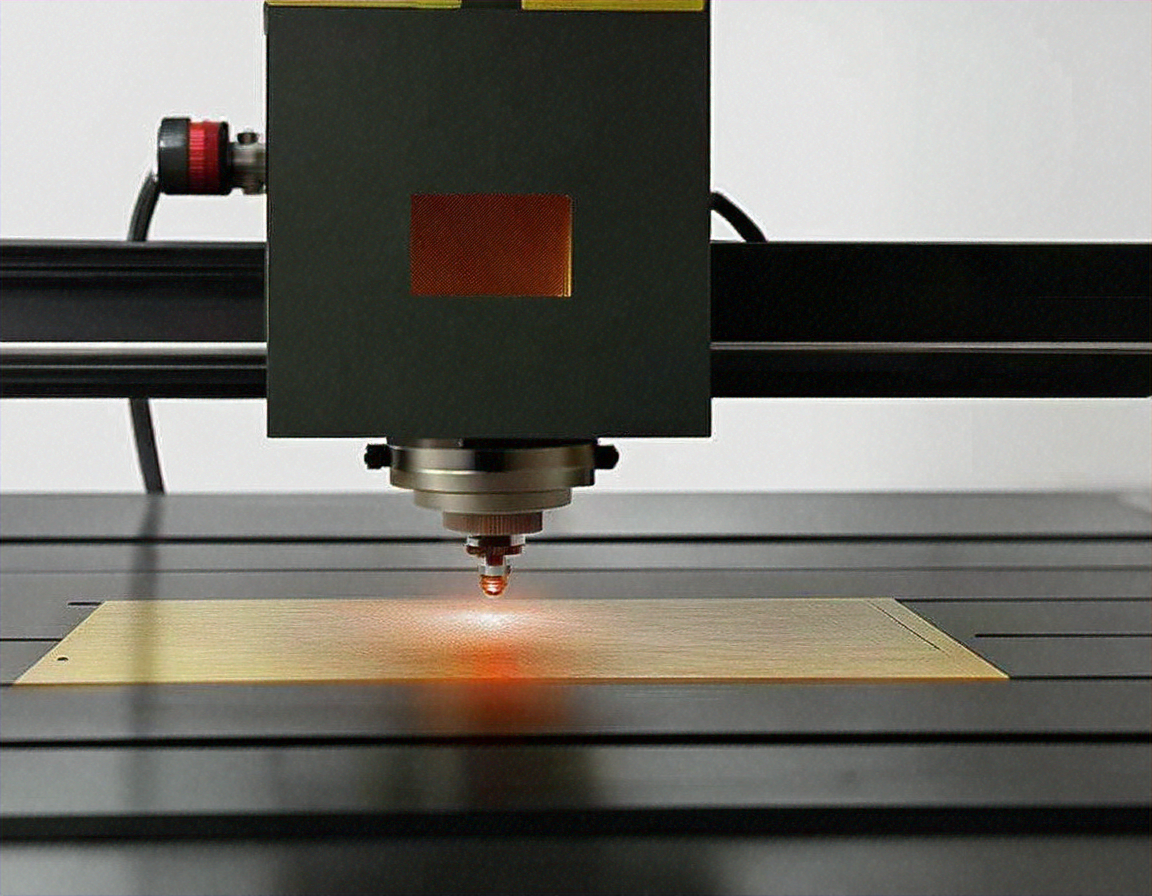

Portable laser welding systems utilize fiber laser technology to generate concentrated light beams that create precise weld joints. These machines typically feature integrated cooling systems, power supplies, and control units housed within wheeled chassis or backpack-style configurations. The laser source generates coherent light at specific wavelengths optimized for material absorption, while beam delivery systems guide the energy through flexible fiber optic cables to handheld welding heads.

Most portable units operate within power ranges of 1000W to 2000W, providing sufficient energy density for welding thin to medium-thickness materials. Advanced models incorporate real-time monitoring systems that adjust parameters automatically based on material thickness and joint configuration requirements.

Benefits of Portable Laser Welding Machines in Field Applications

Portability transforms welding operations by eliminating the need to transport large workpieces to fixed welding stations. This mobility reduces project timelines significantly, particularly for repair work, maintenance operations, and on-site fabrication tasks. The precision offered by laser welding creates narrow heat-affected zones, minimizing material distortion and reducing post-weld finishing requirements.

Energy efficiency represents another key advantage, as laser welding systems convert electrical energy to useful welding energy more effectively than traditional arc welding methods. This efficiency translates to reduced operating costs and lower environmental impact during extended operations.

The non-contact nature of laser welding eliminates electrode consumption and reduces consumable costs compared to conventional welding processes. Additionally, the clean welding process produces minimal spatter and fumes, creating safer working conditions and reducing cleanup time.

How to Find Portable Laser Welding Machines for Your Needs

Selecting appropriate portable laser welding equipment requires careful evaluation of specific application requirements and operational constraints. Power output capabilities should match the thickness ranges of materials typically processed, while beam quality specifications determine achievable weld precision levels.

Weight considerations become critical for handheld operations, as operator fatigue directly impacts productivity and weld quality consistency. Battery life specifications for cordless models must align with expected work duration requirements, while charging time capabilities affect overall operational efficiency.

Cooling system effectiveness influences duty cycle capabilities, particularly important for continuous operation scenarios. Service network availability and technical support accessibility should factor into equipment selection decisions, especially for operations in remote locations.

| Equipment Type | Provider | Power Range | Weight | Cost Estimation |

|---|---|---|---|---|

| Handheld Fiber Laser | IPG Photonics | 1000W-2000W | 15-25 lbs | $45,000-$85,000 |

| Backpack Laser System | Coherent | 1500W-3000W | 35-50 lbs | $65,000-$120,000 |

| Cart-Mounted Unit | Trumpf | 2000W-4000W | 200-300 lbs | $80,000-$150,000 |

| Portable Workstation | Raycus | 1000W-2500W | 150-250 lbs | $35,000-$75,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Safety Considerations and Operational Guidelines

Laser welding operations require comprehensive safety protocols due to intense light emission and potential exposure risks. Proper eye protection using laser safety glasses rated for specific wavelengths becomes mandatory for all personnel in the work area. Skin protection prevents burns from direct or reflected laser exposure, while respiratory protection addresses potential fume inhalation risks.

Ventilation requirements vary based on materials being welded and operational environments. Adequate airflow removes welding fumes and maintains acceptable air quality levels throughout work areas. Emergency shutdown procedures should be clearly established and communicated to all operators before beginning welding operations.

Maintenance Requirements and Service Considerations

Portable laser welding machines require regular maintenance to ensure consistent performance and extend equipment lifespan. Optical component cleaning schedules prevent contamination buildup that could affect beam quality or cause damage to expensive laser components. Cooling system maintenance includes filter replacement and coolant level monitoring to prevent overheating issues.

Calibration procedures verify beam alignment and power output accuracy, ensuring weld quality consistency over time. Preventive maintenance schedules typically include daily visual inspections, weekly cleaning routines, and monthly comprehensive system checks performed by qualified technicians.

Portable laser welding technology continues advancing rapidly, with improvements in power density, beam quality, and system integration expanding application possibilities across numerous industries. Understanding these systems’ capabilities and limitations enables informed decision-making for organizations considering portable laser welding integration into their operations.