Foundational Aspects of Steel Building Construction

Steel has long been a cornerstone of modern construction, celebrated for its strength, durability, and versatility. In the realm of building shelters, its properties offer significant advantages, making it a preferred material for structures designed to withstand various environmental conditions and serve diverse purposes. Understanding the fundamental aspects of steel building construction is crucial for anyone considering its application, from small utility buildings to large-scale industrial complexes. This material provides a robust framework for long-lasting and resilient structures.

What Defines Steel Shelter Structures?

Steel shelter structures encompass a broad category of buildings primarily constructed using steel components for their main framework. These structures can range from agricultural storage facilities and workshops to emergency shelters, commercial warehouses, and even certain types of residential buildings. The defining characteristic is the use of fabricated steel beams, columns, and trusses, often pre-engineered, which allows for rapid assembly and consistent quality. This method of construction leverages the inherent strength-to-weight ratio of steel, enabling large clear spans and open interior spaces without the need for numerous internal supports. The design flexibility of steel also permits a wide array of architectural styles and functional layouts, adapting to specific site requirements and operational needs, making it a versatile choice for many applications.

Essential Design Considerations for Steel Shelters

Designing a steel shelter involves several critical considerations to ensure its structural integrity, functionality, and longevity. Engineers and architects must factor in local building codes, seismic activity, wind loads, and snow loads, all of which directly influence the required strength and dimensions of steel components. For instance, buildings in hurricane-prone regions will demand enhanced bracing and connection details to resist uplift forces, while those in snowy climates need robust roof designs to handle heavy snow accumulation. The intended use of the shelter dictates internal layout, access points, insulation requirements, and utility provisions. For example, a commercial warehouse might prioritize large bay doors for vehicle access and high ceilings for vertical storage, whereas an agricultural building could focus on ventilation and ease of cleaning. Material selection, including the specific grade of steel and protective coatings, is also vital for resisting corrosion and extending the life of the structure, particularly in harsh or corrosive environments, ensuring the building remains functional and safe over decades.

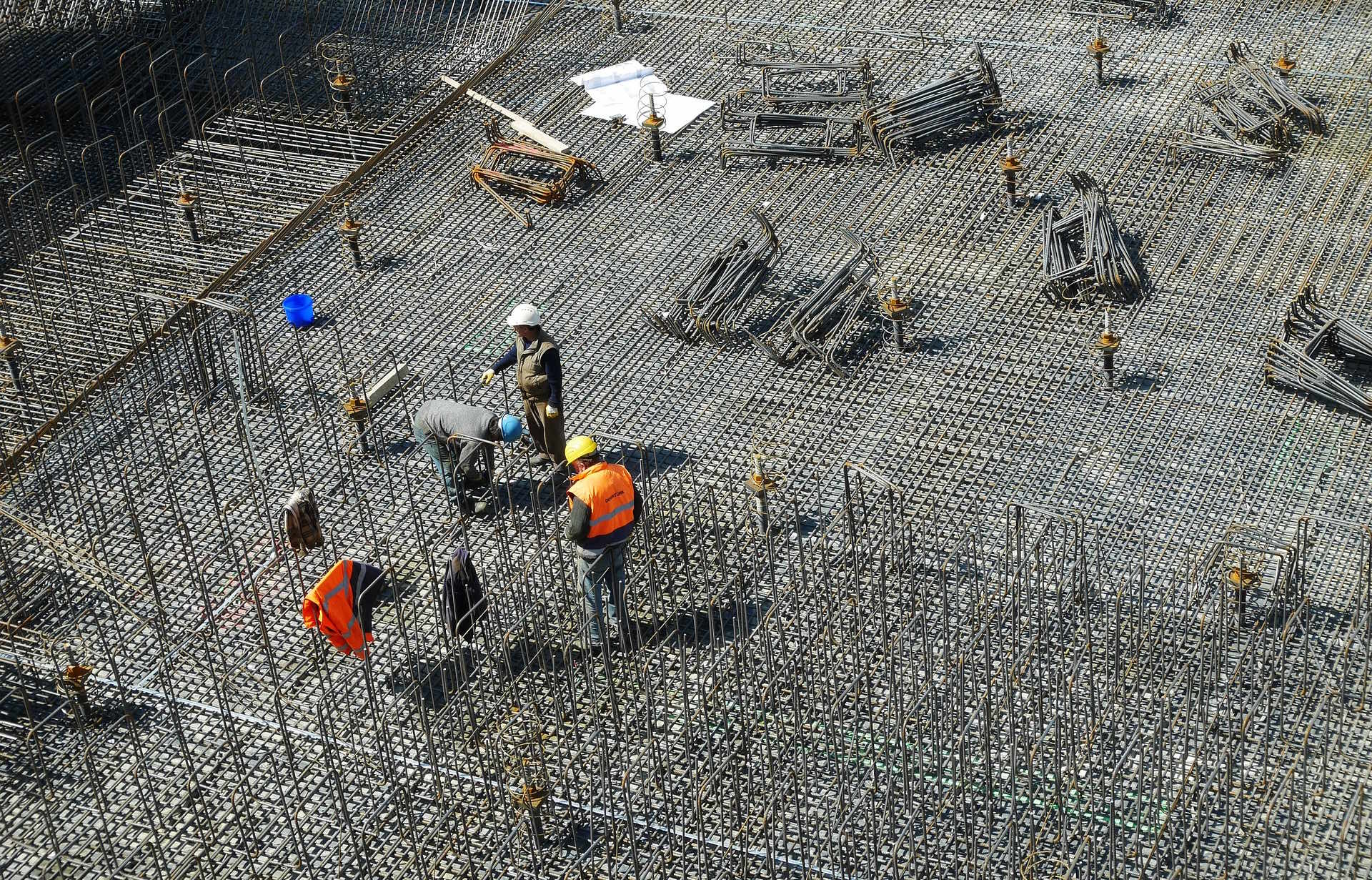

The Construction Process for Steel Buildings

The construction of steel buildings typically follows a systematic process that prioritizes efficiency and precision, beginning long before components arrive on site. It starts with comprehensive site preparation, including grading and utility installation, followed by the pouring of a robust foundation designed to adequately support the steel frame. Once the foundation has cured, the pre-fabricated steel components—such as columns, beams, purlins, and roof trusses—are delivered to the site. These elements are manufactured off-site under controlled conditions, ensuring high quality and precise dimensions. Erection then commences, with skilled crews using cranes and other heavy machinery to lift and position the components, which are then securely bolted or welded together according to detailed engineering drawings. This modular approach significantly reduces on-site labor and construction time compared to traditional building methods. After the main frame is complete, secondary structural elements like girts for walls are installed, followed by the application of roofing materials, wall panels, doors, windows, and any specified interior finishes. Throughout this process, rigorous quality control checks are integral at each stage to ensure strict adherence to design specifications, safety standards, and overall structural integrity.

Benefits of Utilizing Steel in Shelter Construction

Steel offers numerous advantages that make it a highly desirable material for shelter construction across various sectors. Its exceptional strength-to-weight ratio and ductility allow structures to withstand extreme weather conditions, including high winds, heavy snow loads, and seismic events, providing enhanced safety and resilience for occupants and contents. Steel is also inherently non-combustible, contributing significantly to fire safety, and is impervious to pests like termites and rot, which can be significant concerns with organic building materials. The pre-fabrication process, where components are manufactured off-site, leads to quicker construction times, reducing overall project schedules and associated labor costs. Furthermore, steel is a highly recyclable material, making it an environmentally conscious choice that aligns with sustainable building practices. The long lifespan, minimal maintenance requirements, and inherent durability of steel structures also translate to lower long-term ownership costs, offering significant economic benefits over the life of the building compared to alternatives that may require more frequent repairs or replacements.

Maintenance and Longevity of Steel Shelters

Ensuring the long-term performance and appearance of steel shelters requires a proactive approach to maintenance. While steel is inherently durable, it is susceptible to corrosion if not properly protected. Regular inspections for signs of rust, especially in coastal or industrial environments, are crucial. Protective coatings, such as paint or galvanization, should be maintained and reapplied as needed to shield the steel from moisture and other corrosive elements. Fasteners and connections should be checked periodically to ensure they remain secure and free from damage. Keeping the surrounding area clear of debris and ensuring proper drainage can also prevent moisture accumulation that might compromise the structure. With diligent maintenance, a steel shelter can easily last for many decades, providing reliable service and retaining its structural integrity, making it a sound investment for diverse applications.

Steel building construction offers a compelling solution for a wide array of shelter needs, combining structural strength with design flexibility and efficiency. From the initial design considerations to the final stages of construction and ongoing maintenance, the inherent properties of steel contribute to durable, resilient, and cost-effective structures. Its adaptability to various environments and functions underscores its role as a fundamental material in modern infrastructure, providing reliable shelter solutions across numerous applications.